The cross-sea tunnel project is the first super-cross-sea project in China to pass through a karst-developed area with a large diameter. The tunnel needs to pass through a honeycomb karst area. There are three major karst cave groups with a maximum cavern height of 29 meters and the karst rate is 13.7%. The karst caves are explored in three ways: drilling + CT + advanced drilling; 3D exploration of karst caves status; construction under the guidance of spatial-temporal relationship of shield tunneling and karst caves. Thus, the BIM platform needs to be introduced into the project.

BIM platform application overview

SuperMap and partner company has established standard models, shield groups, and BIM management platforms for tunnel construction, which has realized the visualization expression of tunnel shield environment with the goal of dynamic shield safety risk management based on BIM informationization and the safety risk management of the construction site, and provided applications of multi-source geological modeling, geological prediction, shield safety risk management, and guidance for construction and others.

Basic data

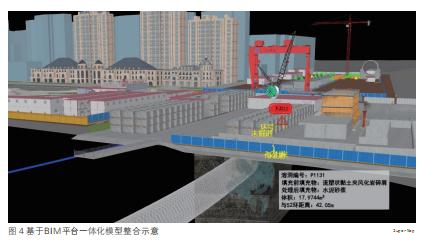

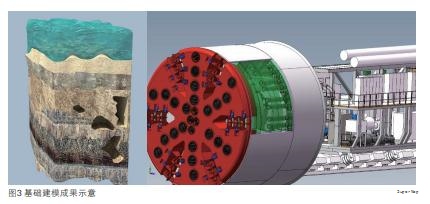

The environmental modeling includes establishing models of risk sources and buildings on the ground, importing BIM platforms, and displaying projects in virtual reality; geological model includes making 3D geological models based on drilling and CT related geophysical data; the shield tunnels modeling includes the modeling of shield machine, tunnel segment, track, pipeline, lining, etc., the model can be imported into the BIM platform after light-weighting.

The project is based on the BIM platform and uses WGS84 (3D GIS) as the structure to form a integrated model which has clear layers of ground, underground, land and sea.

Data Integration

The BIM platform integrates real-time shield machine data, camera monitoring data, intelligent monitoring data (settling, deformation, displacement, stress, pressure, groundwater level, etc.), provides manual monitoring report data importing and mobile inspection reporting, and integrates third-party security hidden danger system data, etc. By integrating multi-party data and comprehensive visual analysis, the islands of information can be avoided and construction safety can be ensured.

BIM platform development and implementation

The BIM full life cycle management platform is based on the SuperMap GIS 3D underlying engine platform and intermediate conversion tool software. Based on the concept of integration and collaboration, it runs through the entire life cycle of the project to realize the management of BIM collaborative design results during the design phase, safety management, progress management, construction phase, quality management, cost management, asset management and maintenance management during operation and maintenance.

The project is implemented in layers based on a full life cycle management framework and a full-environment BIM + 3D GIS line and network application based on the WebGL engine. It is compatible with a variety of modeling software and lightweight processing, and an innovative multi-code integrated 2D and 3D management. Also, the system integrates a variety of data comprehensive analysis, starts from actual business needs, and under the goal of the project landing guidance construction to realize the smart operation and maintenance services by construction data.

Security Risk Management Application

The designer of the project provides risk source information, measurement point information, monitoring solutions, monitors and manages the integrated data. The video monitoring is deployed at the subsea wellhead point, segment assembly point, slag outlet point, and other points, which generates data on mobile APP. Through multi-code 2D and 3D correlation positioning, the analysis and early warning can be conducted and the disposal processes and track statistics can be initiated.

Quality Management Application

The inspection app can submit quality problems and locates them. The problem list is associated with the 3D model and GIS coordinates. Users can view the quality problems and automatically initiate the process, perform process tracking, quality problem statistics, collect measures to build a quality management knowledge base, and finally achieve automatic discovery of problems to match disposal measures and knowledge output.

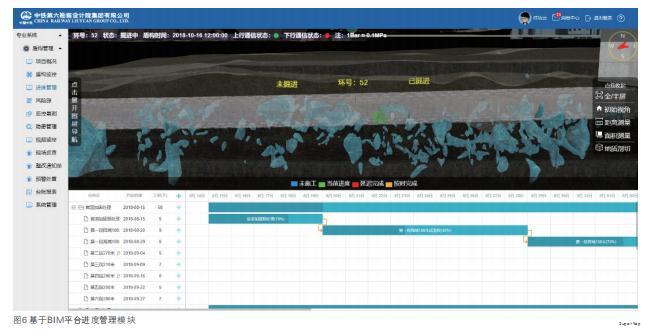

Progress management application

The platform can import project and excel format to visualize the progress of the project. Through construction log and the system's integrated shield machine, the real-time data can be obtained and the abnormal situations can be analyzed and handled to ensure the project schedule.

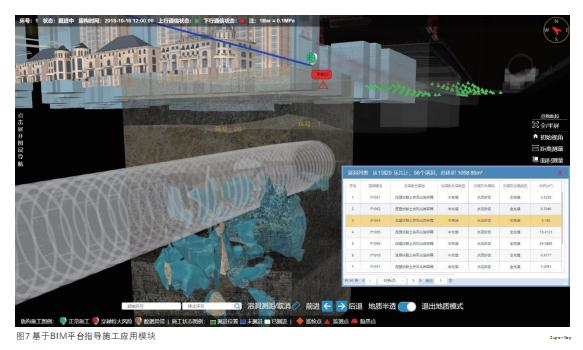

Construction application

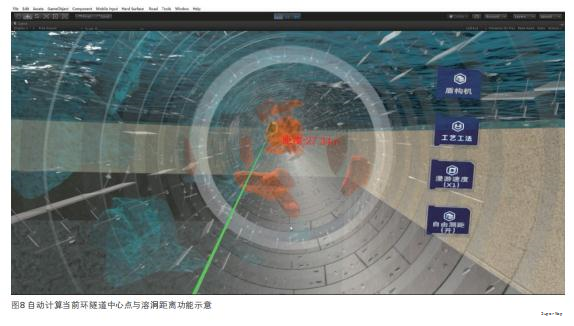

The platform can view the space-time relationship between the position of the shield machine and the surrounding karst in real-time, identify important hidden safety hazard nodes in advance, and deal with them in advance. The main functions of the platform are: geological semi-permeability/solid viewing, geological sectioning of the tunnel face, measuring the distance between the current position of the shield machine and the nearest three caves, querying the karst volume at a certain distance and analyzing the grouting data.

BIM + 3D visualization brings more effective influence

Through the BIM platform, there are some effective influences: 3D visualization of crossovers can be improved efficiently and it saves construction time for 72 days; guides the project construction and saves 5% of karst disposal materials, about 10 million RMB; simulates the space-time relationship between shield rectification, karst and shield tunneling, it can greatly reduce the excavation error and karst risks.

During the implementation of the project, the preliminary summary of innovations, highlights and experiences that can be shared are as follows:

Multi-source geological modeling guides the construction

The project is the first tool in China that implements comprehensive modeling of drilling and CT data, simulates geological conditions, and analyzes real-time shield tunneling and geological conditions, which can provide a basis for analysis of grouting anomalies, thrust anomalies, and settlement anomalies, and assists decision-making.

Comprehensive visual data management of multi-source security risks

The project takes a 3D GIS platform as the carrier and integrates real-time monitoring reports, intelligent monitoring instrument data, video monitoring data, hidden safety system data, and shield machine parameters based on the 2D real-time parameters of the original shield machine.

Automatic calculation of geological prediction

Through the distance between the center point of the tunnel and the cave, the the current point of the shield can be automatically located, and the distance from the surrounding cave can be automatically calculated, which provides a basis for the safe tunneling.

2D and 3D integration maintenance methods of multi-code integration

Based on the construction of the subway multi-code, such as EBS, WBS, and OBS, the model is associated with GIS coordinates, segments, ring numbers, structures, components, etc., and it solves key bottlenecks in BIM information management.

BIM+GIS in Building Information Management>

BIM+GIS Application in Life Cycle Digital Management of Yalong River Hydropower>

BIM+GIS Application in Urban Rail Transit System>