Inspur Software Technology Co., Ltd. (hereinafter referred to as Inspur) is a software product and solution provider for industry applications. Relying on its own advantages in big data, cloud computing, and the Internet of Things, Inspur has joined hands with SuperMap and formed an intelligent safety production supervision platform (hereinafter referred to as the "Platform") based on SuperMap iServer 10i, SuperMap Cloud GIS application server platform. The platform integrates security situation, emergency command, disaster prevention and mitigation, law enforcement summary, jurisdiction supervision, video surveillance and other functions.

The platform can provide sensing monitoring and early warning, remote dynamic inspection and supervision, and other capabilities. The data is fully connected and collected layer by layer to achieve "one network, one game" for safe production.

At the same time, Inspur pioneered a new model of "zero government investment and co-construction of digital security service center" to efficiently address government safety supervision and enterprise safety management, which will truly improve the inherent safety of enterprises, and consolidate the main responsibility of enterprises.

Digital Twin Enterprise

Clear enterprise information

In the process of management and operation, enterprises generate a large amount of data, such as basic geographic data, enterprise operation thematic data, dynamic monitoring perception data, risk hidden danger data, etc. They are scattered among the enterprises in the jurisdiction, and are collected and output in isolation from each other.

How to break the barriers between data and effectively connect these data to serve the operation of the park is a fundamental problem that the platform must solve.

In order to standardize and unify access data, the platform has established a set of standard specifications for data management, data update and data use based on BIM + GIS technology. By collecting new data and using existing data, basic geographic data, thematic data and IoT perception data are collected, and the data is governed and integrated to form a unified spatial data resource library.

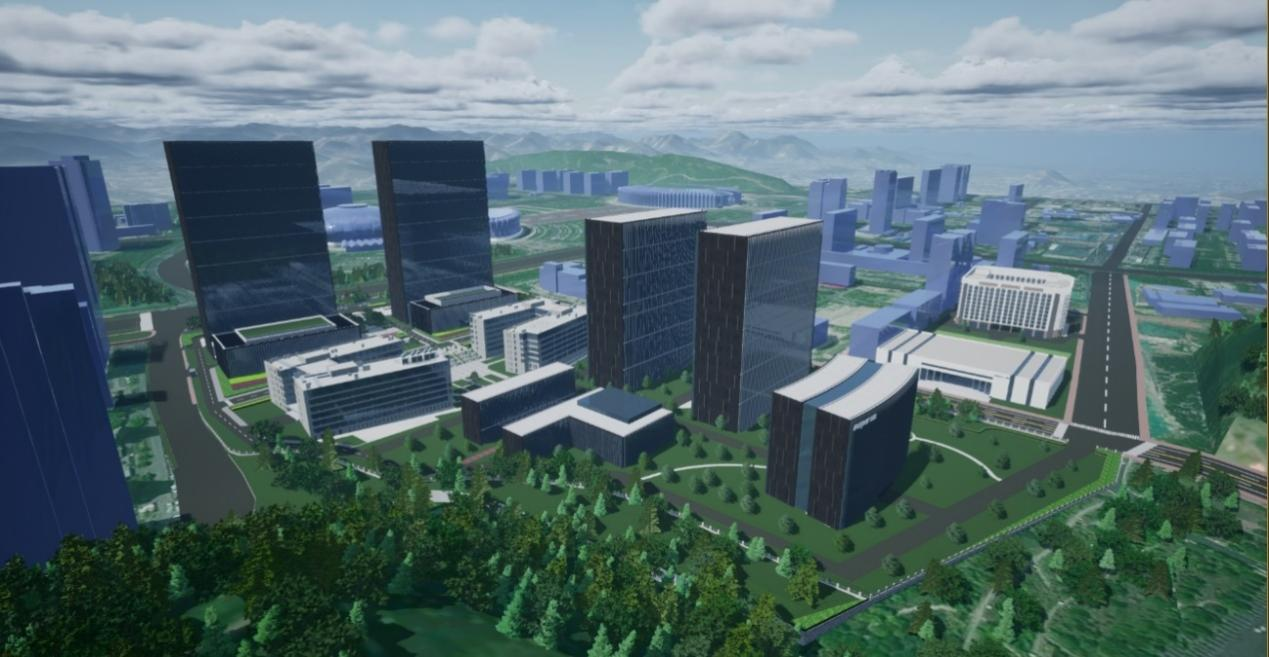

Based on SuperMap’s 2D and 3D GIS technology, various 3D data are integrated and displayed on the map. Various enterprise resources, including buildings, vehicles, equipment assets, events and other information, are integrated and displayed on the map to build a 3D map of enterprise safety supervision and achieve a "clear bottom line" for enterprise information.

Classification of risks

To comprehensively identify and assess the safety risks of enterprises in the jurisdiction, the platform uses GIS technology to integrate information such as enterprise risks, public area risks and major hazards into a 3D visualization map of enterprise safety supervision, so as to achieve clear classification and presentation of safety risks of enterprises in the jurisdiction.

Deeply integrating BIM and IoT perception, the platform links the location and information of various intelligent devices in the enterprise, and marks the location and operating parameters of various sensor devices on the map in real-time, including the enterprise infrastructure situation, underground pipeline network status, access control card gates, personnel trajectory, video surveillance, pipe gallery pipelines and other key monitoring data, etc., to perceive the enterprise's security status in real-time.

The platform provides various two- and three-dimensional spatial analysis algorithms and capabilities, builds a digital twin enterprise, and provides resources and capability support for the construction of enterprise management-related applications.

Using video and 3D scene fusion technology, the platform projects the video streams of the company's outdoor and key indoor scenes' monitoring equipment into three-dimensional scenes. It will achieve full-time and spatial stereoscopic fusion of video data and three-dimensional scene data, and realize real-time global control of the overall situation of the monitoring area, thereby better supporting the company's safety, emergency, and routine management.

Real-time indication of the location and operating parameters of various sensor devices

Quick incident response

The platform integrates emergency resources in the jurisdiction to form a map of emergency resources, realizing one-click allocation of emergency materials, and improving emergency response capabilities.

The deep integration of the park, BIM model construction and IoT perception is made to realize the visualization of the command and rescue business process under the emergency handling mode. The event task handling nodes are presented in a timeline, and the command and coordination efforts can be quickly made.

The handling system is based on the event handling process and time tasks, and mainly includes modules such as event reporting, analysis and judgment, activation of plans, command and dispatch, and time evaluation.

Emergency Resources in One Map

"Real-time communication" between government and enterprises

The platform realizes the drawer-style classification and archival management of the government's daily supervision work, and intuitively displays the implementation of the government's safety supervision responsibilities. The government platform and the enterprise platform realize data interconnection and work interaction, which facilitates the government to grasp the enterprise's safety situation in real-time and assist the government in enterprise safety production supervision.

Explore win-win cooperation to improve the capabilities of both government and enterprises

Through SaaS deployment, the platform solves the drawbacks of traditional information construction, such as large investment, long cycle and slow effect. Through lightweight application services, it avoids possible problems such as duplicate construction, waste of resources and demand changes.

The platform can integrate a variety of IoT devices, which can be self-built and accessed in a flexible way. Whether it is the original IoT sensing equipment that has been built or the new intelligent equipment planned in the future, it can be easily accessed through the standard interface to form scalable modular content.

At the same time, the platform's intelligent tool kit and customized intelligent tools can be used to solve basic work problems such as repeated reporting on multiple platforms of enterprises. Through the data collected and gathered during the enterprise's safe production process, the government supervision platform can quickly obtain the enterprise's safe production information and conveniently integrate it into various reporting platforms and dashboards.

On the other hand, a safety production information service team was also established during the platform construction. Through the online + offline dual-line service model, the problems of enterprises "not understanding" safety production management, "not knowing how to use" the platform, and "not willing to use" by personnel were solved.

Safety production digital experts were stationed in key service areas. Under the unified leadership and command of the local emergency management department, technical support was provided for the local digital supervision and the digital operation of enterprises. The multi-dimensional services for enterprises were refined through training, operation and maintenance, and support. The service of enterprises is truly taken as the core to improve the safety production management level of enterprises.