Deep integration of AI makes image production smarter

With the rapid development of AI technology, SuperMap ImageX Pro 2024 is also constantly integrating AI technology to achieve intelligent upgrades in image production. The newly added cloud detection pre-trained model can automatically complete the image cloud filling work and improve the image quality. At the same time, based on AI intelligent terrain data production technology, it provides the ability to automatically repair water elevation to improve the quality of DSM results.

Image cloud removal automation

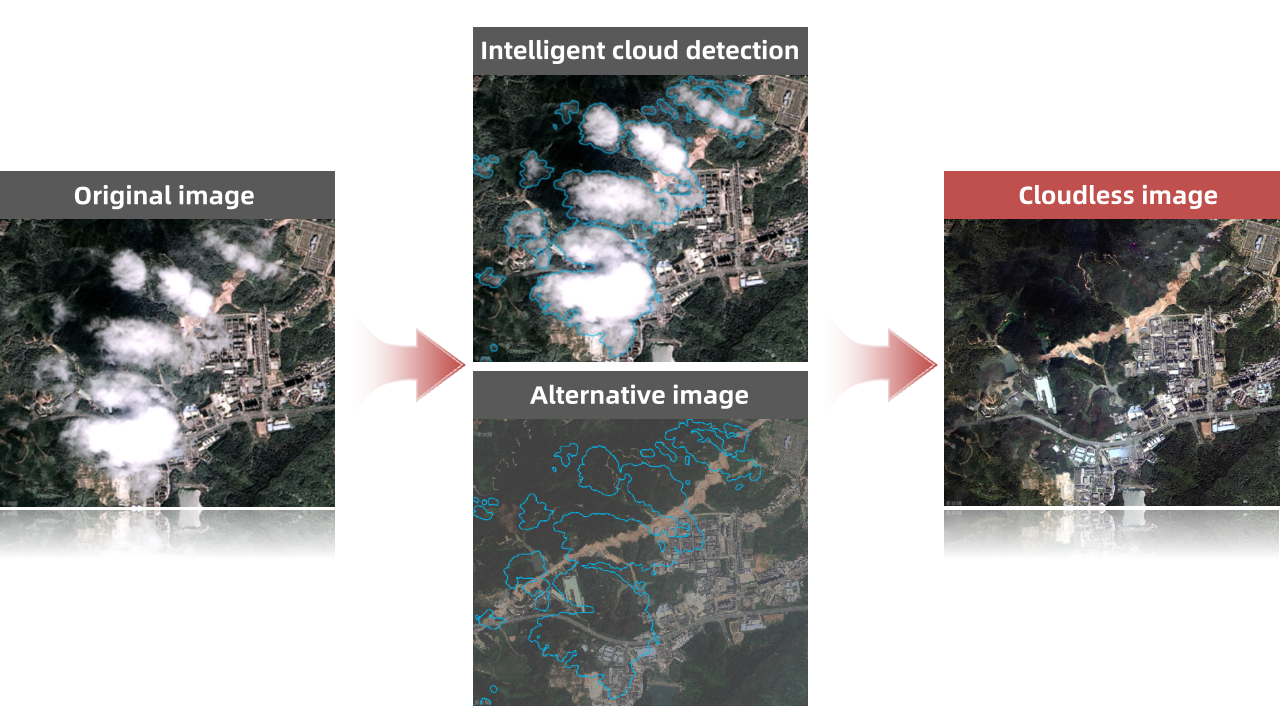

Optical satellite sensors are easily disturbed by clouds in the atmosphere during imaging. Thin clouds can cause blurring of objects, while thick clouds can block objects, affecting the collection and interpretation of land data. SuperMap ImageX Pro 2024 has a built-in cloud detection model that can intelligently detect cloud areas and mosaic the images of the same area in the cloud-free image into the clouded area, while realizing automatic color uniformity processing to obtain image data without cloud obstruction, thereby improving the overall display effect of the resulting image.

Image cloud removal

Water area elevation repair is more accurate

When producing DSM data, it is difficult to match the correct points of the same name because the water area in the remote sensing image is a weak texture area, which will cause errors in the water area elevation value. Therefore, in conventional DSM production, the water area elevation value needs to be manually modified. When processing a large amount of data, manual repair work is inefficient.

To solve the above problems, SuperMap ImageX Pro 2024 has a built-in water area detection model that can automatically extract water areas in images and intelligently repair DSM water area elevation values based on specified elevation values or automatically acquired elevation values, thereby improving the smoothness of the DSM surface, significantly reducing valueless areas, and improving the efficiency of water area repair and the quality of result data.

New quality inspection tools make image production more efficient

In daily image production, it is necessary to test the correction accuracy and edge accuracy of the orthorectified images to understand the error distribution of image correction. However, after orthorectification or image fusion, large mountains, buildings, overpasses and other objects often appear distorted. These problems used to require manual investigation and processing, which was a cumbersome process and a long production cycle.

To this end, SuperMap ImageX Pro 2024 provides image plane quality inspection and fine plane quality inspection tools to quickly locate high-risk areas and improve quality inspection efficiency; it also supports automatic inspection of deformed areas such as mountains, buildings, and road markings without manual intervention.

More precise image quality inspection

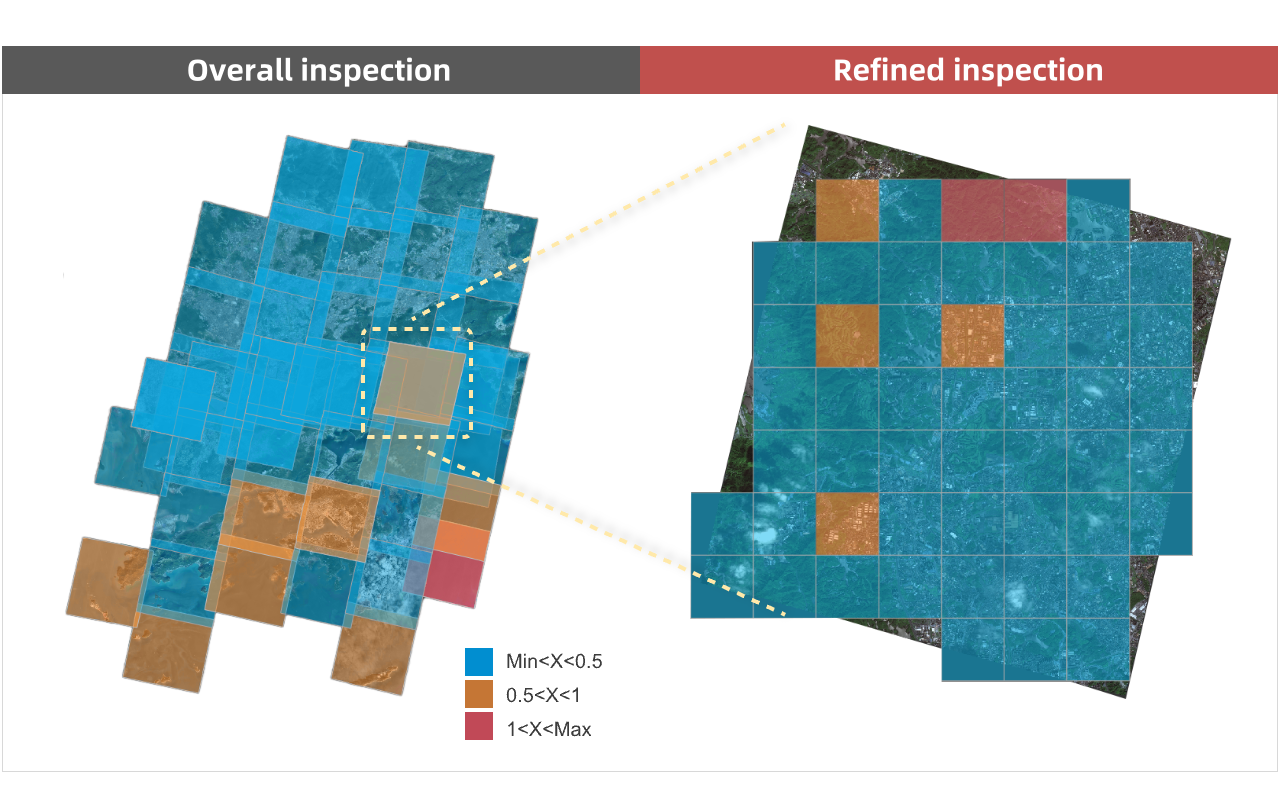

Image quality inspection includes image plane quality inspection and fine plane quality inspection. Image plane quality inspection can detect the plane accuracy and edge accuracy of each image, so as to quickly understand the overall quality, single image quality and edge quality of the image; while fine plane quality inspection divides the inspection area into grids of specified size, detects the image plane accuracy of each block, so as to understand the distribution of orthorectification errors of blocks smaller than each image area.

At the same time, during quality inspection, checkpoints can be automatically generated, and management operations such as hierarchical display, addition, deletion and modification of checkpoints are supported to obtain clearer and more accurate reports.

Image quality inspection

Grating deformation detection saves time and improves work effiency

For a long time, the inspection and repair of deformed areas have relied on manual processing. However, with the explosive growth of satellite image data and the increase in the workload, manual inspection and repair can no longer meet the needs of production operations, and more efficient automatic detection and repair methods are urgently needed. Therefore, the pattern deformation detection tool came into being, which can automatically detect the areas of mountain, building, and road pattern deformation, greatly improving work efficiency.

Algorithm upgrade to achieve high computing performance

In the process of image data production, a large amount of intermediate data will be generated. This data will not only take up a lot of storage space, but also affect processing efficiency. In actual production applications, some businesses only need to focus on the final results. To solve these problems, SuperMap ImageX Pro 2024 further improves production performance based on raster function chains. Experimental tests show that data production that originally took 372 minutes can be completed in just 73 minutes through raster function chains.

Conclusion

SuperMap ImageX Pro 2024 continues to explore and research algorithms, keeping up with the latest developments in AI technology, and is committed to making remote sensing image production more powerful and more stable. For more details, please visit SuperMap's official website to download and experience it.