Pipelines are important infrastructure that ensures the operation of the city. They are called the "lifeline" of the city and carry important functions such as information transmission and water and electricity resources transportation. With the rapid development of cities, the types of urban pipelines are becoming increasingly diverse, widely distributed, dispersed, and highly concealed. As a result, operators and managers face severe challenges to realize refined planning and management of pipelines.

To this end, SuperMap has developed a 3D pipeline full-process management technology. After years of technological exploration and accumulation, SuperMap 3D pipeline full-process management technology can realize a series of pipeline data functions from access, expression, processing, analysis, service release to multi-terminal applications, providing effective technical support for the planning and construction, operation management and emergency disposal of 3D pipelines in urban planning, municipal construction, oil and gas storage and transportation, environmental protection and other fields.

Technical advantages

The 3D pipeline full-process management technology provided by SuperMap has the following advantages:

Based on parametric modeling and symbolic modeling capabilities, 3D pipeline scenes can be quickly constructed, which can significantly reduce construction costs and difficulties. It can also improve the display performance of 3D pipe points and pipelines, and greatly improve the data bearing capacity of the scene by effectively reducing memory usage, thereby meeting the management needs of large-scale complex 3D pipe networks.

It supports a set of data to be used on desktop, web, mobile, game engines and other multi-end applications.

It can quickly improve the visualization of 3D pipeline scenes through the material editor and material mapping.

It provides rich 3D spatial analysis and query functions to meet the planning and approval, verification management, operation and maintenance and other full life cycle application needs of pipeline.

It provides rich APIs to help developers quickly customize personalized 3D pipeline comprehensive management systems.

Functional module

SuperMap 3D pipeline full-process management technology includes the following contents:

01 Data access

The data access function supports accessing original pipeline data to the SuperMap GIS platform. Currently, SuperMap iDesktopX supports direct access to original pipeline data in .shp/.csv/.mdb/.dwg and other formats, including the pipeline's plane position, burial depth (or elevation), direction, nature, specifications, material, construction time and ownership unit and other information.

02 Data inspection and correction

To ensure the correctness of the 3D topology network and pipe well modeling, users need to check whether there are errors in the accessed original pipeline data and whether the attribute fields are complete. If there is a problem with the data, it needs to be corrected and then checked again until the check passes. In addition, when the data does not have an elevation field, it needs to be filled in based on relevant information. For example, the pipe point elevation can be obtained by subtracting the burial depth and pipeline radius from the ground point elevation.

03 Data conversion

3D pipe point data and 3D pipeline data are the basic data for constructing 3D network data sets. The original pipeline data obtained through pipeline detection technology is usually 2D (two-dimensional) data, so the original 2D pipe point and pipeline data need to be converted into 3D point and line data through the data conversion function.

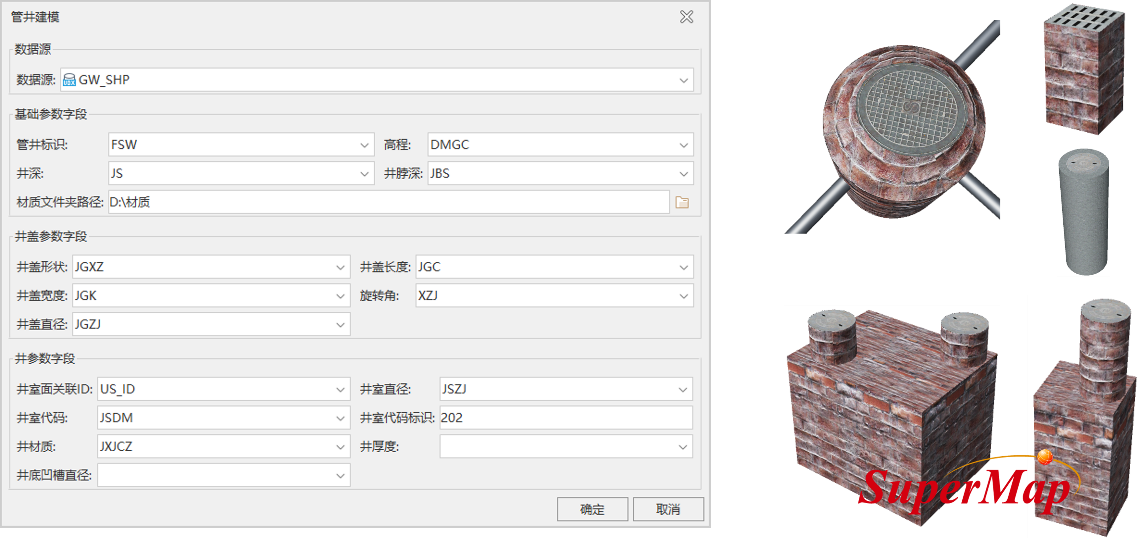

04 Tube well modeling

In order to build precise tube well models quickly and in batches, SuperMap iDesktopX provides a tube well modeling function that supports the construction of tube well models based on original 2D pipeline data through parametric modeling technology, thereby accurately expressing various types of complex tube wells.

Tube well modeling

05 3D topology network

The 3D network data set is the data basis for 3D network analysis and rapid construction of 3D pipeline scenes. SuperMap iDesktopX supports the construction of 3D network data sets with spatial topological relationships based on 3D pipe point data, 3D pipeline data or network data sets.

It should be noted that since the resources transported by real 3D pipelines have a certain flow direction, only 3D network data sets with spatial topological relationships can better express 3D pipelines, simulate the real-time flow effect of oil and other resources in pipelines, and carry out various 3D network analysis.

06 Pipe points and pipeline symbols construction

There are a large number of different feature points, manholes and ancillary facilities in the 3D pipeline scene. In order to break through the dilemma of manual modeling which is time-consuming, labor-intensive and difficult to maintain, SuperMap iDesktopX supports the construction of 3D adaptive pipe point symbols, 3D point symbols, and 3D line symbols, and can save them in the symbol library for repeated use. The 3D point symbols are used to express wells, valves, water meters and other ancillary facilities; the 3D linear symbols are used to express 3D pipelines; 3D adaptive pipe point symbols are used to express turning points, branch points, intersections, change points, elbows, multiple feature points such as through points. Moreover, relying on the topological relationship between pipe points and pipelines in the 3D network data set, 3D adaptive pipe point symbols can effectively solve the matching problem of pipe points such as elbows and tees with pipelines in the scene.

07 3D pipeline scene construction

After the above data processing is completed, SuperMap iDesktopX supports the rapid construction of 3D pipeline scenes using customized thematic maps. In this process, symbolic modeling technology played a crucial role.

Symbolic modeling technology automatically constructs a 3D pipe point model and a 3D pipeline model in real-time based on the pipeline direction, pipeline section and other parameters in the 3D network data set, and the constructed 3D pipe point model and 3D pipeline model can be seamlessly connected.

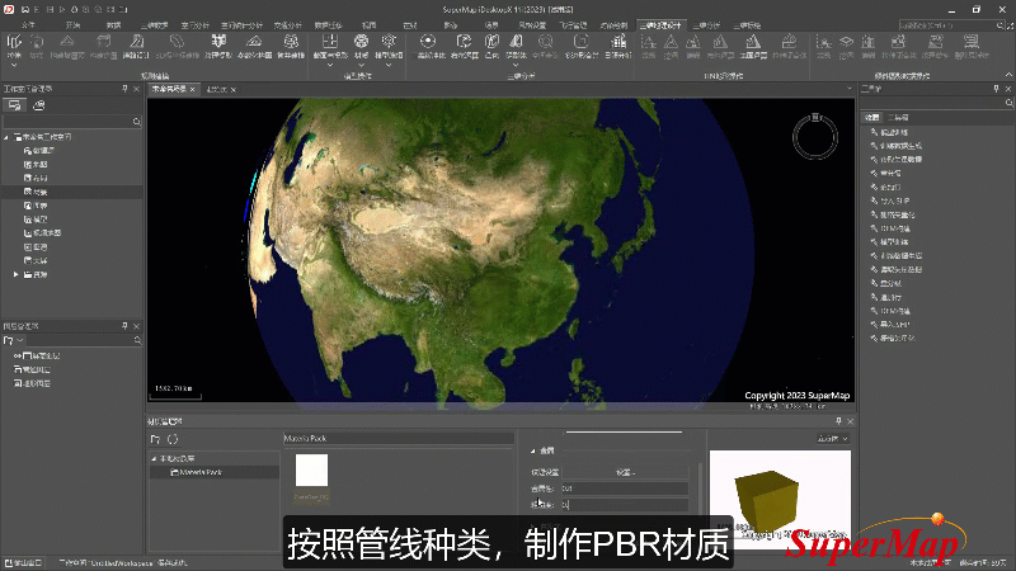

In addition, in order to improve the visualization effect of the 3D pipeline scene, SuperMap iDesktopX supports using the material editor to create PBR materials that are suitable for multi-pipeline business and assign them to the pipeline model.

3D pipeline scene construction

08 Service release

In order to implement multi-terminal applications of 3D pipeline scenes and 3D network analysis functions, SuperMap iServer supports publishing 3D network data sets as 3D network analysis services, and publishing 3D tiles (S3M) generated based on 3D pipeline scenes as 3D services.

09 Multi-terminal applications

In order to realize the sharing and interoperability of 3D pipeline data, SuperMap iDesktopX supports generating 3D pipeline scenes into 3D tiles (S3M).

Currently, multiple platforms and software such as desktop, mobile, web, and game engines all support loading, visualization, and applying 3D pipeline scenarios stored using S3M tiles. They also support using 3D network analysis capabilities and 3D pipeline scenarios by loading 3D network analysis services and 3D services.

SuperMap iClient3D for WebGL loading oil station S3M data with PBR material

More capabilities

In order to meet the actual pipeline management needs and help quickly build a 3D pipeline comprehensive management system, SuperMap GIS also has the following functions:

It supports the fusion and matching of multi-source data such as pipelines, terrain, urban fine models, and oblique photography 3D models.

It supports multiple pipeline data browsing methods such as above ground, underground, rolling shutter, split screen comparison, etc.

Pipeline data browsing

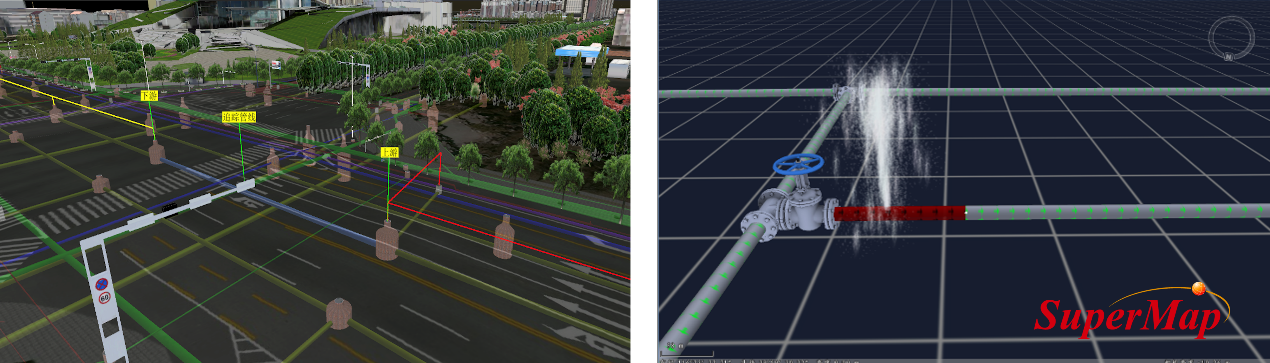

It provides basic functions such as profile analysis, 3D buffer analysis, and 3D measurement, and can be combined to realize pipeline horizontal/longitudinal profile analysis, clear distance analysis, burial depth analysis, overburden analysis, accident analysis, information query, and statistics.

3D pipeline upstream and downstream tracking (left) and pipe burst analysis (right)

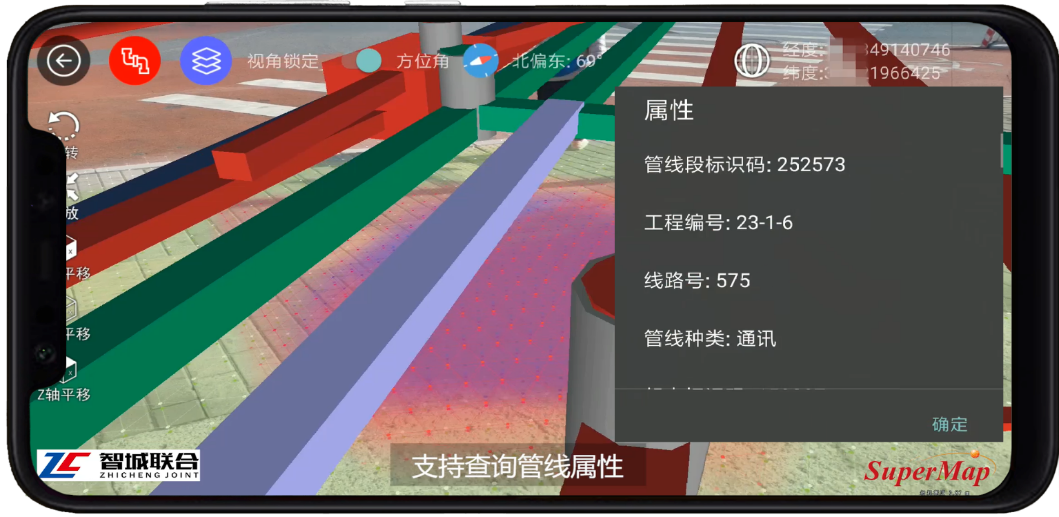

Mobile inspection function based on AR+GIS, which can accurately match underground pipelines with the actual scene, thereby quickly viewing pipeline attribute information in real-time, and assisting in completing services such as fault alarms.

Mobile inspection

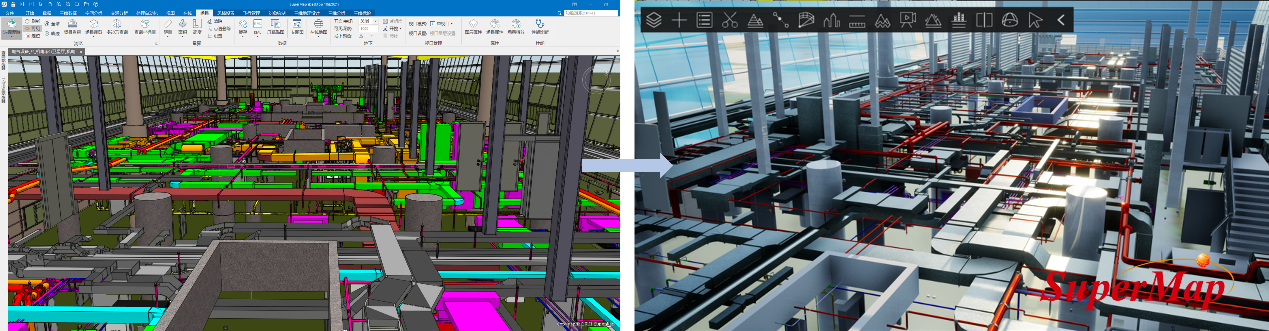

It supports the accessing, processing and service release of electromechanical pipeline BIM data to multi-end applications, and can quickly map game engine materials based on S3M data to achieve high-fidelity visualization of pipeline data.

Quickly mapping game engine materials based on S3M data and beautifying electromechanical pipeline data

In the future, SuperMap GIS will continue to improve the full-process management technology of 3D pipelines, enrich parametric modeling functions such as tube well modeling, and optimize the capabilities of multi-terminal application of 3D pipeline scenarios to further meet the application needs of the smart pipe network industry and be better compatible with the upstream and downstream links.