In recent years, with the maturity of 5G, industrial Internet, cloud computing and other technologies, and the deep integration of new generation information technology and manufacturing, the construction of smart cities is no longer limited to concepts. As an important component and form of expression of smart cities, the building of smart park will also become the "next outlet" for park development.

Compared with general industry parks, chemical industry parks may introduce problems of high pollution and high risk. Facing the development requirements of the new era, the chemical industry park will continue to upgrade its industry with the help of digital twin and geospatial intelligence technology, and evolve towards the direction of intelligent construction.

SuperMap's Intelligent Solutions for Smart Chemical Industry Park

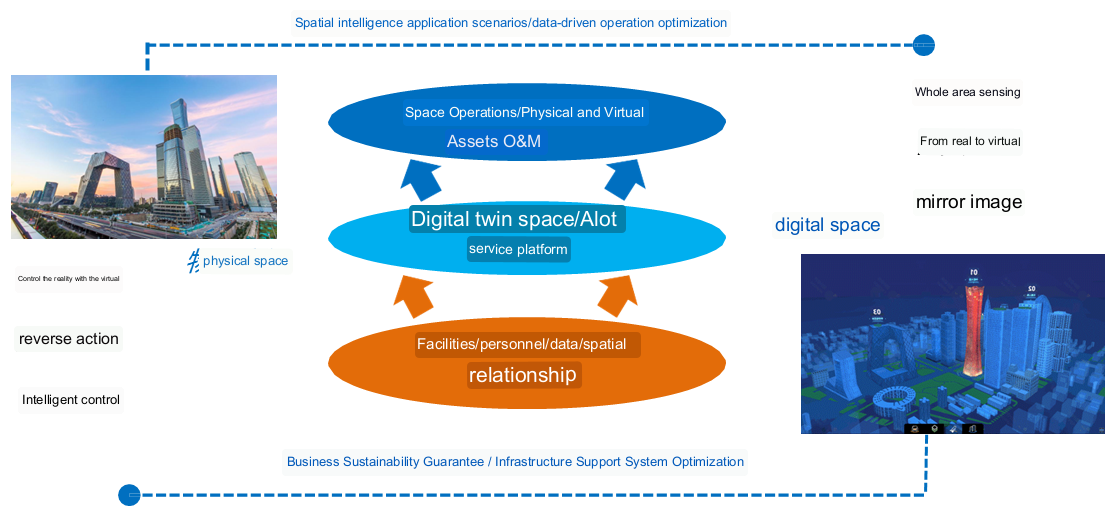

With the integration of geospatial intelligence technologies, SuperMap has developed a solution plan to build smart industrial park. With the intelligent platform for digital twin chemical industry park at it center, the plan incorporates diverse data type. By leveraging the powerful Digital Twin IOC application, the programme enables dynamic visualization, situational awareness, and comprehensive analysis and other functions.

Programme Mechanisms

The intelligent platform of digital twin chemical industrial park achieves service and management for users at all levels. It ensures timely detection, handling, and resolution of various issues arising during the operation of the park through digitization, visualization, standards, and dynamic flow. It gradually establishes a comprehensive management mechanism with clear division of labor, clear responsibilities, efficient communication, rapid response, timely disposal, and efficient operation.

Conceptual Model of SuperMap Digital Twin Campus

Programme Components

The solution constructs data resources, builds an intelligent platform, constructs a digital twin IOC and a full-field business application design to empower the operation of chemical parks.

1.Constructing Multi-Source Heterogeneous Fusion Data Resources

1.1 Basic geographical database: It is a spatial data base that collects various types of geographic entities in the chemical park, such as ground, buildings, roads, water systems, green areas, pipeline corridors, etc. It is composed of point, line, surface vector elements and high-resolution images, and covers the spatial data of the park on the ground, underground, indoor and outdoor at multiple scales and with multiple elements. By adopting the standardized organization mode of basic geographic information databases, it ensures high precision and multi-element of the park.

1.2 3D model database: It is the core part of the digital twin platform in the smart chemical park, which contains 3D data such as tilt-shift photography model, 3D precise model, laser point cloud model, etc. It is the spatial base for depicting the main body of the park and the current situation of the park. With the definition and conversion of S3M data format, the heterogeneous 3D model data from multiple sources can reach a deep fusion, realizing the integration of macro/micro, all-scene and all-dimension data in the park.

1.3 BIM lifecycle database: It is a centralized repository for construction data within the chemical industry park. Built upon various levels of BIM models, it digitally integrates design proposals, construction drawings, wiring data, maintenance and inspection records, covering the park's entire lifecycle activities from planning, assembly, maintenance, to dismantlement. This database assists park managers in addressing challenges related to lifecycle information integration and facilitating continuous development and upgrades.

1.4 Business thematic database: This database consolidates various business data, including daily management, investment operations, and equipment and facilities maintenance within the chemical industry park. By integrating business information with spatial models, it enables visual representation and analysis of business data. The fusion of business and spatial information widens the scope and depth of business data analysis, aiding managers in making more informed and precise decisions regarding park operation and management.

1.5 Indicator database: It revolves around various themes within the chemical industry park, such as resources, industries, investment, and services, to create an indicator analysis repository. This database provides managers with the operational status of the park and rule-based conditions for predicting future trends. The business indicator analysis data in the system helps managers analyze and assess the operational trends of the park, enabling proactive intervention rather than passive responses in daily park management from park managers, thereby promoting orderly park operations.

2. Building the Intelligent Digital Twin Chemical Industry Park Platform

2.1 SuperMap 2D-3D integration GIS platform: It refers to a geographical information platform that integrates the functionalities of a 2D Geographic Information System (GIS) and a 3D Geographic Information System (3D GIS). It can process and display 2D and 3D geographical data simultaneously with a unified data model and user interface, providing comprehensive geospatial information analysis and visualization capabilities. It includes data integration and management, multi-dimensional data analysis, 3D visualization and simulation, 2D-3D integrated display, application development and customization.

2.2 SuperMap data governance central platform: This is a central platform that integrates functions such as data management, data quality management, data security management, and data compliance governance. As the core structure of data governance, it offers unified interfaces and functionalities to manage and ensure the integrity, accuracy, consistency, and security of internal organization data. This includes data management, data quality management, data security management, data compliance governance, and data governance process management.

2.3 SuperMap IoT central platform: It integrates functionalities such as hardware device management, data collection and storage, data analysis and visualization, and application development into a central platform. As the core structure of the IoT system, it provides unified interfaces and functionalities to connect and manage various devices in the IoT, collect, process, and analyze the vast amount of data generated by the IoT, and support the development and deployment of various applications.

2.4 SuperMap digital twin base: It provides an integrated environment for collecting, storing, processing, and analyzing data related to the digital twin and supports simulation, optimization, and decision-making for physical systems. The SuperMap Digital Twin Base realizes data integration and storage for the chemical industry park, integrating various data sources from physical systems, including sensor data, monitoring data, workflow data, etc. It unifies the storage and management of these data, providing the data foundation for the digital twin model.

3. Constructing the Digital Twin IOC (the Brain of the Chemical Industry Park)

Targeting the operational management department of the chemical industry park, this platform integrates cutting-edge technologies such as Artificial Intelligence (AI), 5G communication, Internet of Things (IoT), Big Data, Building Information Modeling (BIM), Geospatial Intelligence (GI), and Digital Twins. It encompasses multiple scenarios, including data collection, equipment management, comprehensive analysis, environmental protection, energy consumption monitoring, emergency command and dispatch, business management, property management, personnel management, event management, and integrated safety and security. The platform serves as a multi-functional display and service platform, supporting the four major construction objectives of "safety and reliability, convenience and efficiency, green and low-carbon, and people-oriented."

An illustration showcasing the Digital Twin IOC

4. Business Application Design Across All Fields.

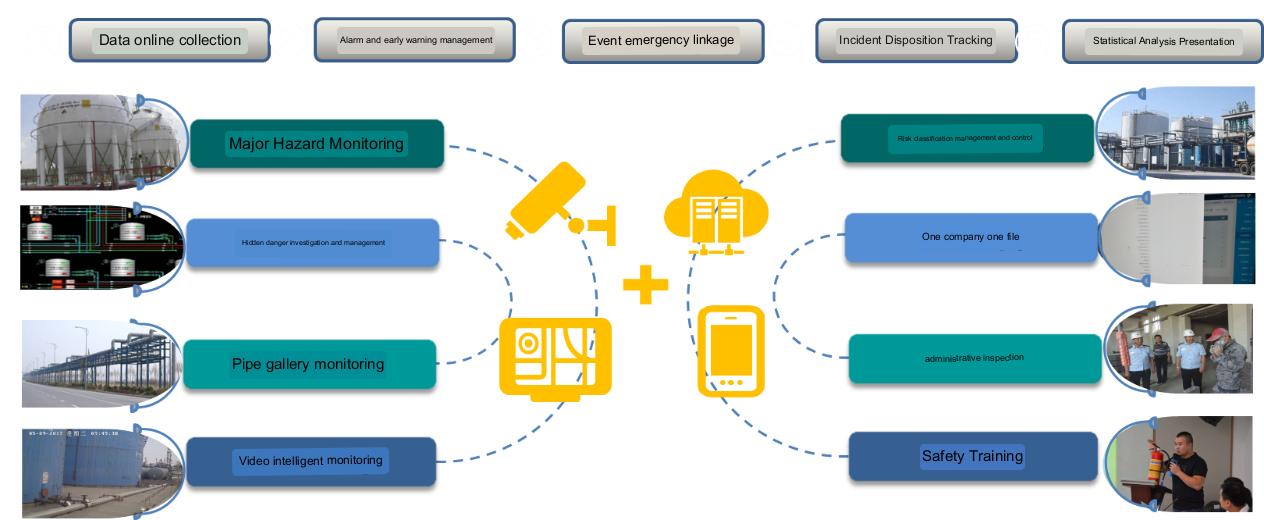

4.1 Production safety: Leveraging the intelligent risk control platform, comprehensive and effective management is conducted for risk classification and control; investigation, and remediation of hidden hazards; monitoring and risk warning of major hazardous sources, on-site operation control, safety administrative law enforcement management, and special equipment risk warning management.

Intelligent Chemical Industry Park Safety Production and Construction Content

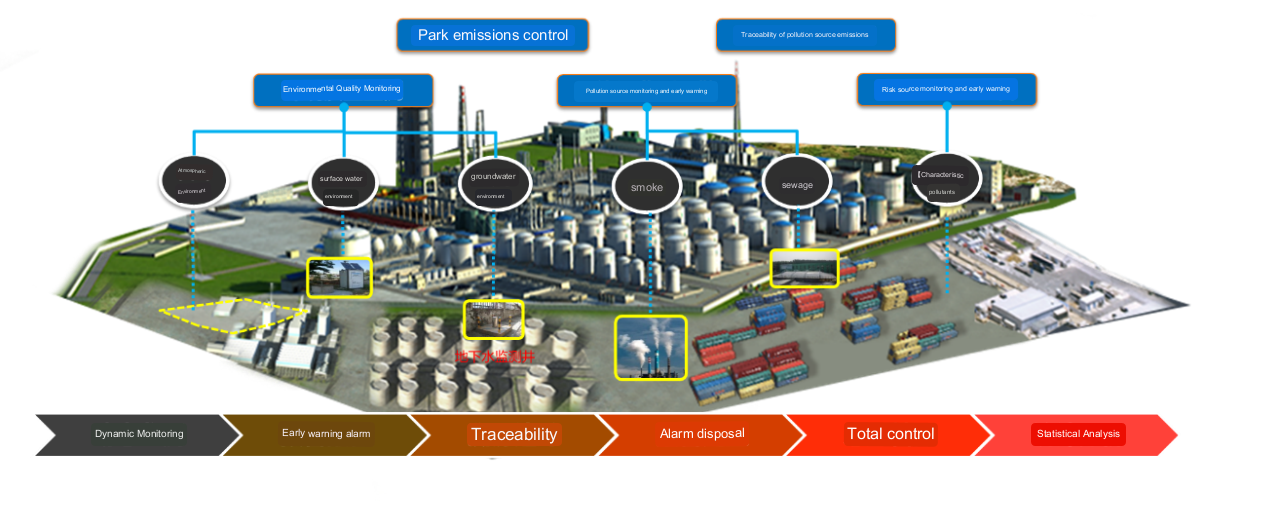

4.2 Environment management: By establishing an environment monitoring system, it consolidates and displays data from monitoring sensors and surveillance videos of various environmental aspects in the park, such as air quality monitoring points, water environment quality monitoring points, hazardous chemical enterprises' wastewater discharge outlets, and exhaust emission outlets. Additionally, combined with the park's SMS push platform, it provides daily information push, offering comprehensive data support for environment monitoring and management in the chemical industry park.

Intelligent Chemical Industry Park Environment Management Construction Ideas

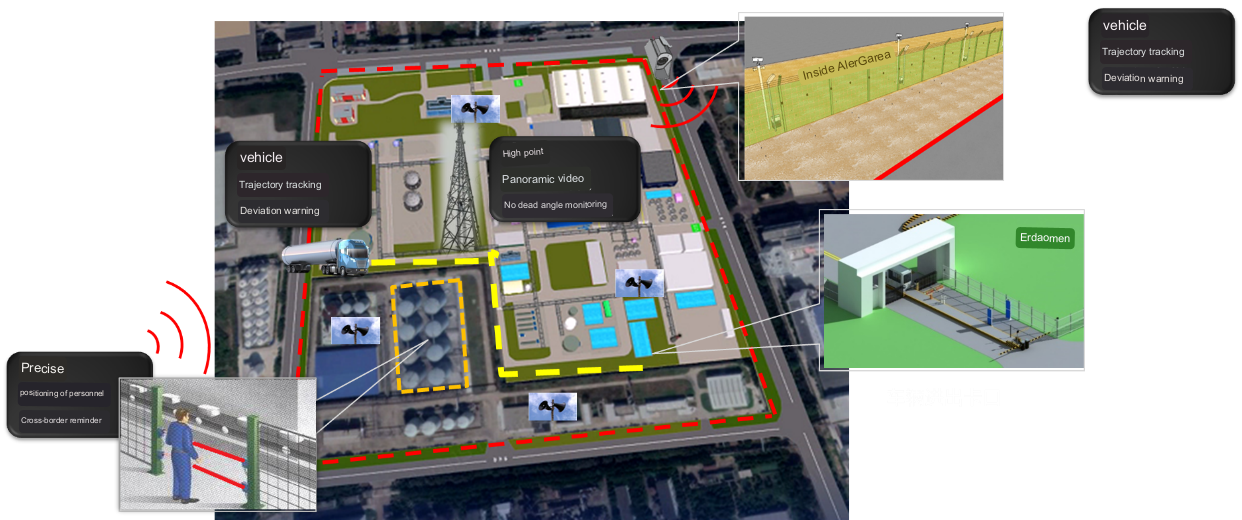

4.3 Closed management: By setting up monitoring cameras in the perimeter, and deploying pedestrian-vehicle diversion at the park entrances and exits to identify the vehicles entering and exiting the park (road gate system), and the personnel (access control system), the platform realizes the panoramic video monitoring in the park without dead angle, the video linkage of abnormal behaviors and unlawful intrusion and other alarms, and quick notification, as well as the functions of public security patrol management, identification of key vehicles, positioning tracking of vehicles and people and timeout reminding.

Intelligent Chemical Industry Park Closed Management Simulation

4.4 Transportation management: The intelligent logistics system uses GPS monitoring, GIS geographic services, mobile intelligent technology, RFID radio frequency scanning, wireless video transmission, one-card services and other high-tech to strictly review the qualification of the platform of hazardous chemical vehicles; conduct real-time supervision of vehicles carrying hazardous chemicals in the park, and management of mobile hazardous sources; master the dynamics of the chemical logistics integrated with the enterprise logistics orders; and automatically load platform online transactions according to regional system judgement.

Intelligent Chemical Industry Park Transport Management Simulation

4.5 Energy management: By aligning with the enterprise energy management system, it accurately assesses the energy usage of the park and businesses. Through specialized energy optimization services, it ensures the sustainability of energy optimization, thereby assisting the park in achieving its energy-saving and consumption reduction goals.